electrical panel maintenance protocol pdf

The importance of maintaining electrical panels cannot be overstated. This guide‚ developed in collaboration with regulators‚ provides a comprehensive protocol to ensure safety‚ compliance‚ and optimal functionality.

Overview of Electrical Panel Importance

Electrical panels are critical for distributing power safely and efficiently within a building. They protect circuits from overloads‚ ensure reliable power supply‚ and serve as the central hub for electrical systems. Proper maintenance is essential to prevent hazards like fires or equipment damage‚ ensuring compliance with safety standards and regulations. Regular upkeep also extends the lifespan of electrical systems‚ maintaining operational efficiency and safety for users. Neglecting panel maintenance can lead to severe consequences‚ making it a top priority for facility management.

Objective of the Maintenance Protocol

The primary objective of the maintenance protocol is to ensure electrical panels operate safely and efficiently. It outlines procedures to identify and address potential issues‚ prevent system failures‚ and comply with regulatory standards. By following this protocol‚ technicians can extend equipment lifespan‚ reduce downtime‚ and minimize risks of electrical hazards. Regular maintenance also supports optimal power distribution‚ ensuring reliability and performance across all connected systems. This structured approach is vital for safeguarding both personnel and infrastructure from electrical-related incidents.

Regulatory Compliance and Safety Standards

Adherence to local and national electrical codes is crucial for ensuring safety and efficiency in panel maintenance‚ preventing hazards and guaranteeing inspections meet established standards.

Local and National Electrical Codes

Compliance with local and national electrical codes is essential for ensuring safety and efficiency in panel maintenance. These codes‚ such as the National Electric Code (NEC) in the U.S.‚ provide detailed guidelines for installations‚ inspections‚ and repairs. Adhering to these standards helps prevent hazards and ensures systems operate reliably. Regular updates to codes reflect advancements in technology and safety practices‚ making it crucial to stay informed. Proper labeling and documentation‚ like circuit breaker directories‚ are also mandated to facilitate safe and efficient maintenance practices.

Safety Guidelines for Panel Maintenance

Safety is paramount in electrical panel maintenance. Always de-energize the panel before starting work‚ using lockout/tagout procedures to prevent accidental power restoration. Wear appropriate PPE‚ including insulated gloves and safety glasses‚ to protect against electrical hazards. Ensure proper ventilation and avoid working in areas with flammable materials. Never bypass safety devices‚ and use tools rated for the voltage levels involved. Maintain a safe distance from live components and keep emergency contact information readily available. Regular training on safety protocols is essential for all personnel involved.

Tools and Personal Protective Equipment (PPE)

Essential tools include multimeters‚ wire strippers‚ and thermal imaging cameras; PPE such as insulated gloves‚ safety glasses‚ and arc-rated clothing are crucial for safe maintenance practices.

Essential Tools for Panel Maintenance

Multimeters‚ thermal imaging cameras‚ and wire strippers are vital for diagnosing and repairing electrical panels. Screwdrivers‚ pliers‚ and circuit testers are also necessary. These tools ensure accurate measurements‚ safe handling‚ and effective troubleshooting‚ helping to identify faults and prevent potential hazards during maintenance tasks.

Required PPE for Safe Maintenance Practices

Protective gear like arc-rated clothing‚ insulated gloves‚ and safety glasses are essential. Hard hats and non-conductive footwear also prevent injuries. These items ensure adherence to safety standards‚ minimizing risks during electrical panel maintenance. Proper PPE use is crucial for safeguarding against electrical shocks‚ arcs‚ and other hazards‚ ensuring a secure working environment for technicians.

Pre-Maintenance Inspection Checklist

A thorough inspection ensures safety and efficiency. Check for loose connections‚ damaged components‚ and signs of wear. Use thermal imaging to detect hidden faults before starting work.

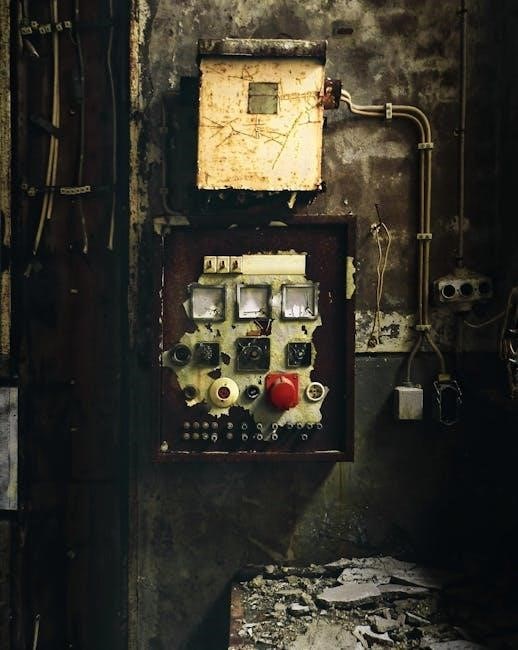

Visual Inspection of Panel Components

Begin with a visual examination of all panel components‚ including circuit breakers‚ busbars‚ and connectors. Look for signs of wear‚ rust‚ or discoloration‚ which may indicate overheating. Check for loose connections‚ damaged labels‚ or exposed wires. Ensure all components are securely fastened and properly aligned. Verify that circuit breakers are functioning correctly and that no unusual odors or sounds are present. This step helps identify potential issues before they escalate‚ ensuring a safer and more efficient maintenance process.

Thermal Imaging for Fault Detection

Thermal imaging is a non-invasive method to detect temperature anomalies in electrical panels. Using an infrared camera‚ technicians identify overheating components‚ such as loose connections or overloaded circuits‚ before they cause failures. This technique is especially useful for predicting potential issues early‚ ensuring proactive maintenance. Regular thermal scans help prevent electrical fires and unexpected shutdowns‚ making it a critical tool for maintaining safety and efficiency in electrical systems. It complements visual inspections by revealing hidden faults invisible to the naked eye.

Internal Inspection Procedures

Internal inspections of electrical panels involve detailed checks of components such as circuit breakers‚ busbars‚ and connectors. Technicians ensure all connections are tight and free from corrosion. They also verify that all internal wiring is properly routed and secured. Any signs of wear or damage are documented for immediate repair. This thorough process ensures the panel operates safely and efficiently‚ preventing potential hazards like arcing or short circuits. It is essential to conduct these inspections with the panel de-energized to ensure technician safety.

Maintenance Tasks and Procedures

Regular electrical panel maintenance involves inspecting connections‚ cleaning debris‚ and replacing worn components to ensure safe and efficient operation‚ as outlined in the protocol.

Cleaning and Debris Removal

Cleaning electrical panels is essential to prevent overheating and ensure proper functionality. Use compressed air or soft-bristled brushes to remove dust and debris from surfaces and components. Avoid harsh chemicals or abrasive materials that could damage equipment. Regularly vacuum internal areas to eliminate dust buildup. Always de-energize the panel before cleaning and wear appropriate PPE to ensure safety. This step is critical for maintaining electrical integrity and preventing potential hazards.

Tightening Connections and Fasteners

Tightening connections and fasteners is a critical step in electrical panel maintenance. Use a torque wrench to ensure all terminals‚ busbars‚ and connectors are securely fastened to manufacturer specifications. Check for loose screws‚ especially in high-current areas like main breakers and neutral bars. Inspect for signs of wear or corrosion and replace damaged components. Properly tightened connections prevent arcing‚ overheating‚ and potential fires‚ ensuring reliable power distribution and system safety. Always reference the panel’s specifications for torque values.

Replacing Damaged or Worn-Out Components

Replacing damaged or worn-out components ensures the electrical panel operates safely and efficiently. Inspect for signs of wear‚ such as cracked insulation‚ frayed wires‚ or corroded connections. Use replacement parts that meet or exceed original specifications. Turn off the power supply and verify de-energization before starting work. Follow manufacturer guidelines for installation to prevent mismatches or substandard performance. Proper replacement prevents potential hazards like short circuits or arcing‚ maintaining system reliability and compliance with safety standards. Document all replacements for future reference and maintenance planning.

Troubleshooting Common Issues

Troubleshooting common electrical panel issues is crucial for preventing unexpected outages and potential hazards. Common problems include circuit breaker tripping‚ overheating‚ and power fluctuations. Addressing these issues promptly ensures system safety and reliability.

Identifying Overheating Signs

Overheating in electrical panels can lead to serious safety hazards. Key signs include unusual warmth‚ discoloration‚ or a burning smell. Use thermal imaging to detect temperature anomalies. Check for loose connections‚ overloaded circuits‚ or damaged components. Regular inspections and infrared scanning help identify potential issues early. Addressing overheating promptly prevents equipment failure and fire risks‚ ensuring system reliability and safety. Always follow safety protocols when investigating overheating issues to avoid personal risk or further damage.

Addressing Circuit Breaker Tripping

Circuit breaker tripping indicates potential overloads or short circuits. First‚ identify the tripped breaker and reset it if safe. Check for overloaded circuits or faulty devices. Inspect wires for damage or loose connections. Use a multimeter to test for short circuits. Regular maintenance‚ such as tightening connections‚ can prevent recurring issues. Ensure circuit loads are within rated capacities to avoid frequent tripping. Always adhere to safety guidelines when troubleshooting to prevent electrical shocks or further damage.

Diagnosing Power Fluctuations

Power fluctuations can indicate issues such as loose connections‚ overloaded circuits‚ or faulty components. Use a multimeter to measure voltage levels and identify irregularities. Check for damaged wires or corroded terminals‚ and ensure all connections are secure. Thermal imaging can detect hotspots caused by faulty components. Addressing these issues promptly prevents equipment damage and ensures reliable power supply. Regular inspections and maintenance help mitigate risks associated with power fluctuations‚ ensuring system stability and safety.

Documentation and Record-Keeping

Accurate and detailed records of maintenance activities ensure compliance and provide a clear history for future reference. Maintain logs of inspections‚ repairs‚ and component replacements to track panel health.

Importance of Maintenance Logs

Maintenance logs are crucial for tracking electrical panel upkeep‚ ensuring accountability‚ and verifying compliance with safety standards. They provide a clear history of inspections‚ repairs‚ and upgrades‚ aiding in troubleshooting and planning. Logs also serve as legal documentation‚ protecting against liability claims. Regular updates ensure continuity and help identify recurring issues. Proper record-keeping supports efficient maintenance scheduling and enhances overall system reliability‚ making it a cornerstone of electrical panel management.

Creating a Circuit Breaker Directory

A circuit breaker directory is essential for organizing and identifying components within an electrical panel. It maps each breaker to its respective circuit‚ simplifying troubleshooting and maintenance. This directory should include breaker ratings‚ circuit numbers‚ and associated loads. Regular updates ensure accuracy‚ while clear labeling prevents accidental shutdowns. A well-maintained directory enhances safety‚ reduces downtime‚ and streamlines repairs‚ making it a vital tool for effective electrical panel management.

Safety Protocols During Maintenance

Adhering to safety protocols during electrical panel maintenance is critical to prevent accidents. Proper lockout/tagout procedures‚ use of PPE‚ and de-energizing circuits ensure a safe working environment. Always follow established guidelines to minimize risks and protect personnel from electrical hazards‚ ensuring compliance with regulatory standards for safe maintenance practices.

Lockout/Tagout Procedures

Lockout/Tagout (LOTO) procedures are essential for ensuring electrical panel safety during maintenance. This involves disconnecting power sources‚ applying locks‚ and tagging circuits to prevent accidental energization. All personnel must follow established LOTO protocols strictly‚ using approved devices to secure equipment. Verification of zero energy state is crucial before commencing work. Proper documentation and communication among team members further enhance safety‚ preventing unauthorized restarts and potential hazards. Compliance with OSHA standards ensures effective implementation of LOTO practices.

Emergency Response Plan

An emergency response plan is critical during electrical panel maintenance to address unexpected incidents like shocks‚ fires‚ or system failures. The plan should outline evacuation routes‚ emergency contact details‚ and first aid procedures. Communication devices and fire extinguishers must be readily available. Team members should be trained to isolate power sources and notify professionals immediately. Regular drills ensure preparedness‚ minimizing risks and ensuring a swift‚ coordinated response to potential hazards.

Best Practices for Electrical Panel Maintenance

Regular maintenance ensures safety and efficiency. Schedule inspections‚ check components‚ and tighten connections. Use proper tools and follow standards to prevent hazards and extend panel lifespan.

Regular Scheduling of Maintenance

Regular maintenance is crucial for ensuring electrical panels operate safely and efficiently. Schedule inspections every 6-12 months to check for loose connections‚ worn components‚ and signs of wear. Preventive maintenance helps avoid unexpected failures and potential fire hazards. Use a comprehensive checklist to ensure all components are evaluated. This practice not only extends the panel’s lifespan but also ensures compliance with safety standards and regulations‚ preventing costly repairs and downtime. Consistency is key to maintaining reliability and safety.

Environmental Considerations for Panel Placement

When placing electrical panels‚ consider environmental factors to ensure optimal performance and safety. Avoid locations with high humidity‚ moisture‚ or exposure to corrosive substances. Panels should not be installed in areas prone to flooding or extreme temperatures. Ensure proper ventilation to prevent overheating and maintain airflow. Protect panels from direct sunlight and dust accumulation. Placement should also comply with local building codes and regulations to guarantee reliability and longevity of the electrical system. Environmental considerations are critical for maintaining panel integrity and safety.